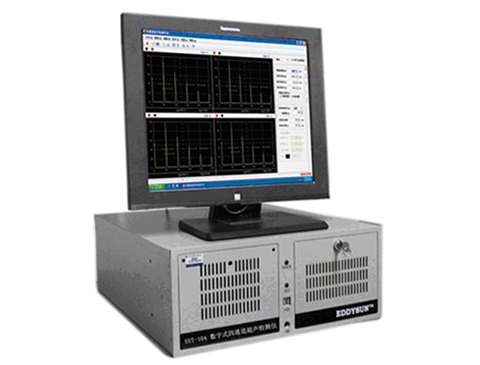

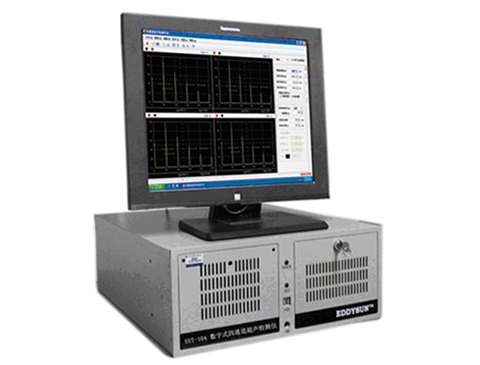

EUT-104 4-channel digital ultrasonic flaw detector

EUT-104 digital four-channel ultrasonic detector consists of EUT-104 four-channel PCI board, industrial computer and special software. EUT-104 four-channel PCI card has the advantages of high repetition rate and high measurement resolution, as well as high sensitivity, complete function, stability and reliability, clear interface and convenient dialogue. It is suitable for colleges, research institutes and factories to quickly compose a multi-channel ultrasonic flaw detector with high performance and multi-function. EUT-104 digital four-channel ultrasonic tester has added many functions to meet the special needs of high-speed automatic flaw detection and thickness measurement of small-caliber thin-walled tubes. When equipped with high-frequency narrow pulse probe, the wall thickness echo of 6*0.5mm steel tube can be clearly detected, which lays a foundation for further analysis.

EUT-104 digital four-channel ultrasonic detector consists of EUT-104 four-channel PCI board, industrial computer and special software. EUT-104 four-channel PCI card has the advantages of high repetition rate and high measurement resolution, as well as high sensitivity, complete function, stability and reliability, clear interface and convenient dialogue. It is suitable for colleges, research institutes and factories to quickly compose a multi-channel ultrasonic flaw detector with high performance and multi-function. EUT-104 digital four-channel ultrasonic tester has added many functions to meet the special needs of high-speed automatic flaw detection and thickness measurement of small-caliber thin-walled tubes. When equipped with high-frequency narrow pulse probe, the wall thickness echo of 6*0.5mm steel tube can be clearly detected, which lays a foundation for further analysis.

1. The instrument can be assembled into 1-4 channels within 4 channels arbitrarily, such as manual inspection of single channel or 2 channels, automatic and semi-automatic inspection of 4 channels with combined probe or simple mechanical transmission device, etc.

2. This card belongs to a high-performance universal multi-channel ultrasonic PCI card. It can easily form an ultrasonic flaw detector with industrial control unit, which has high performance index, complete function and wide application. Therefore, it is especially suitable for colleges and research institutes to carry out flaw detection research.

3. "N Choose 1" is a special function of this instrument for on-site flaw detection with serious white noise and clutter interference.

4. If 1-5MHz broadband narrow pulse probe is used to detect coarse grained materials or other flaw detection tests (such as plate wave test), the instrument settings can be changed according to the requirements on the basis of the above conditions.

5. Various measurement functions of gate make it possible to locate defects accurately; the function of "bottom wave attenuation" of gate d gives the concept of quantity to bottom wave monitoring; the "waveform broadening" of gate b/c provides conditions for observing and analyzing echo details and judging the nature of defects.

6. Different kinds of probes can be used to accomplish different inspection tasks, such as longitudinal wave inspection with a straight probe, shear wave inspection with an inclined probe, surface wave inspection with a surface wave probe, and high resolution inspection with a high frequency narrow pulse probe, etc.

7. B-scan imaging function not only realizes defect visualization, but also stores enough information for further data processing.

8. The stability and reliability of long-time work is the first condition of large forging flaw detector. The instrument has strict control over temperature drift and long-time work drift.

9. High resolution near/far field can be obtained by using high frequency narrow pulse probe, which is especially suitable for the occasion where superficial or minor defects need to be found.

10. Equipped with crawler or mechanical scanner for automatic or semi-automatic inspection

11. The instrument adopts man-machine dialogue interface, which is clear and easy to understand, easy to operate, and helpful hotkey hints.

12. Random computer software can image storage records, call back and play back, analyze or generate reports, print and other functions.

● Transmitted Pulse:Tine Pulse Amplitude≥500V,tr≤15ns● Damping: high / low gear● Single/Double Isolation:≥90dB● Repetition frequency (PRF): 25Hz~10KHz, multi-rang regulating available● Detection range: 3~10000mm (longitudinal wave of steel) , adjustable continuously,minimal display range of 3mm● Shift in pulse: -10~1000mm (longitudinal wave of steel)● Material Velocity:1000~15000 m/s● Frequency: 0.5~25MHz. 2~4MHz、5~15MHz、1~20MHz or 0.5~25MHz four stalls● Gain:0~110dB,with 0.5/2/6dB step● Attenuation Error:No more than ±0.1dB in each 2dB● Vertical Linear Error:≤3%● Horizontal Linear Error:≤0.5%● Detect sensitivity margin:≥60dB● Far field resolution:≥30dB● Measurement resolution:0.01mm● Rejecting:0~80%,Linear rejecting

It is suitable for high-speed automatic flaw detection and thickness measurement of small-caliber thin-walled tubes, multi-channel flaw detection of forgings and water immersion flaw detection, especially for colleges and research institutes to carry out flaw detection research.

- Maglev Related Products

- Maglev Bearing

- Maglev Centrifugal Blower

- Maglev High-speed PMS Motor

- Maglev Molecular Pump

- High Frequency Vector Invertor

- Maglev High-speed turbo vacuum pump

- Maglev Centrifugal desulfurization atomizer

- High-temp. air cooled reactor main blower

- Waste heat recovery maglev generator

- Maglev Turbine compressor

- Energy storage flywheel

- Power Semiconductors

- Vacuum Electron Tubes

- Capacitors

- Ceramic Capacitor

- Ceramic Capacitor Stack

- High Voltage Live Line Ceramic Capacitor

- Rectangular ceramic capacitor

- Voltage sensor/transformer/divider capacitor

- PCC Ultra-thin parallel high frequency high voltage capacitor

- High frequency high voltage ceramic capacitor

- 5G communication RF capacitor

- High power microwave capacitor

- Water Cooled Capacitor

- Vacuum capacitor

- Mica Capacitor

- Super Capacitor

- Trimmer Capacitor

- Aluminum Electrolytic Capacitor

- Film Capacitor

- Power pulse capacitor

- Filter Capacitors

- Special Capacitors

- Snubber Capacitors

- Air variable capacitors

- Ceramic Capacitor

- Resistors

- AC/DC Resistive Load Bank

- Thick Film Power Resistors

- High Voltage Resistor

- Braking Resistor

- Aluminum Housed Resistor

- Wirewound Resistor

- High Power Wirewound Resistor

- Adjustable Resistor

- Water Cooling Resistor

- Blower Motor Resistor

- Cement Resistor

- Film Resistor

- Milliohm Resistor

- Carbon Disc Resistor

- High pulse overload resistance

- Relays

- Sensors & Transducers

- Connectors

- Magnetic Core & Soft Ferrites

- Induction Heating & Welding

- Solid State HF Induction Heating Equipment

- Solid State Superaudio Frequency/ Medium Induction Heating Equipment

- SCR Medium Frequency Induction Heating Equipment

- Vacuum Tube High Frequency Equipment

- Quenching Equipment

- PC Steel Bar Induction Heating Equipment

- Large Power Heating Power Supply

- Cut Off machines

- Saw blades

- Power Electric Equipment

- Electrical Components

- Electric Motors

- Instrument & Meters

- Microwave Devices

- Potentiometers

- TV, Broadcast, FM & RF Devices